top of page

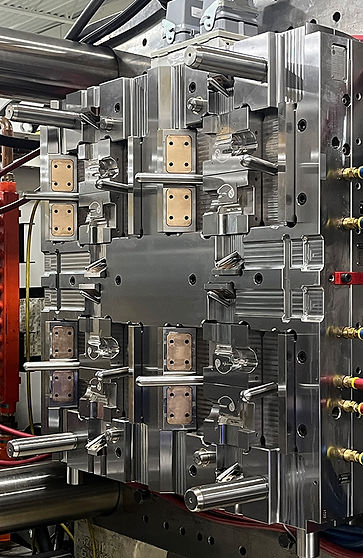

High Productivity Injection Molds

for Medical, Packaging, Personal Care, and Industrial Applications

Engineered to Support High Productivity Molding

ISO 9001:2015 Certified Dynamic Tool Corporation has a 40+ year track record as a trusted provider of plastic injection mold design, building, and validation services. Our customers are globally leading companies in the medical device, personal healthcare, packaging, energy, electronics, water management, and industrial industries.

Core services and capabilities include DFM - design for manufacturing, comprehensive process simulation, conformal cooling, in mold closing / living hinge, auto-unscrew, thin wall applications, collapsible core, insert, and all manner of in-mold-assembly and multishot molding technologies.

Our injection mold machining and manufacturing processes include automated inline quality - via integrated metrology in hard cutter, graphite machining, and sinker EDM cells - for absolute repeatable accuracy. For our customers' applications with stringent tolerance requirements - we will hold 5 microns (0.0002).

We have extraordinary resources and experience in preventive mold maintenance, refurbishment, repair, and engineering change upgrade. Our ability to sample your injection mold onsite, after PM or rebuild services, ensures your mold is ready for production.

Dynamic also provides custom equipment solutions to optimize your production processes.

From prototype to bridge to high cavity / multiple sets of production molds, Dynamic Tool is your Innovation Partner in Performance Solutions.

bottom of page